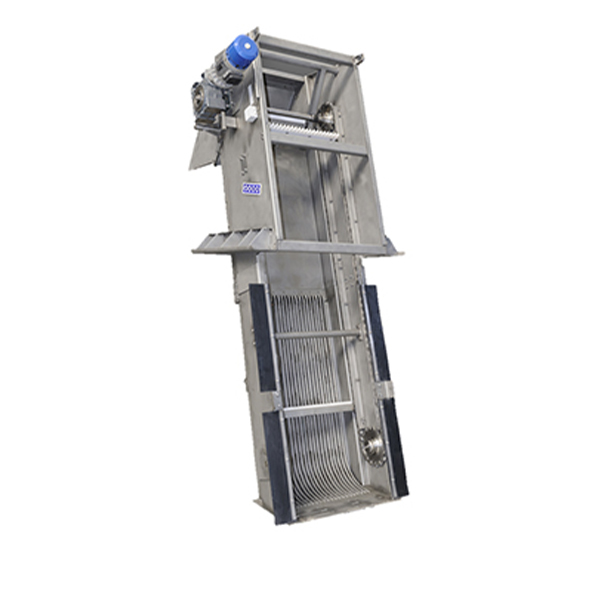

In operation, sewage flows though the inclined screen, approaching from the upstream side and after passing through the screen, departing on the downstream side. The screen is periodically raked by a mechanized comb system which is actuated either by level switches mounted in the channel upstream of the screen or by time clock. A doctor blade at the top of the comb travel removes the screenings collected by the moving combs.

The moving combs are suspended between two endless side chains, which are driven through a head shaft, and sprockets. The gear motor and moving comb system is protected from damage caused by jamming by a torque overload coupling with a micro switch. The screenings removed from the doctor blade drop onto a skid plate, which transports the screening down to a container, belt conveyor or sluice pipe.

Key Features :

- Modular Design: The multi-rack design allows the equipment to be tailored to different applications and capacities.

- High-Strength Materials: Often made from durable materials such as stainless steel, these screens can withstand harsh industrial environments.

- Flexible Configurations: The number of racks and the type of mesh can be customized based on the application, ensuring effective filtration for varying flow rates and types of solids.

Office Address

Saffron/1, Shukan-6 Apartment, Opp. Sciencecity, Sciencecity Road, Sola, Ahmedabad – 380060, Gujarat, (INDIA).

Contact Us

Contact Person: Mr. Nischal Mevada - +91 94266 89986

Email Id: sales.envifab@gmail.com, tech.envifab@gmail.com